|

부스터 펌프(Booster pump)란?

DCS, PLC, PC, or PAS?

Unsure about blurring control system distinctions, users identify

with functionality Control Magazine - July

2001

Bob Waterbury, Senior Editor

Outside of a child's book of fiction, if you read about

converging parallel lines you might be justifiably concerned that the world as

we know it is about to end. But once parallel, now converging, control

technologies are an important trend, and without cataclysmic results.

In

fact, some control industry experts see technological convergence as an

opportunity whose time has come. Larry O'Brien, senior analyst, ARC Advisory

Group, Dedham, Mass., uses the generic term process automation system (PAS) to

describe all forms of DCS, mini-DCS, and hybrid controls (Figure 1). He

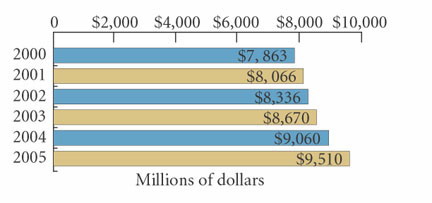

estimates the worldwide PAS market will grow to more than $9.5 billion in 2005,

up from $7.8 billion in 2000 (Figure 2).

One of the issues obscured by

this estimate is that unit cost is declining while functional capability is

increasing. At the same time, overall hardware sales are actually falling, being

supplanted by rises in software and services. Greater functionality at lower

cost means more power for the dollar.

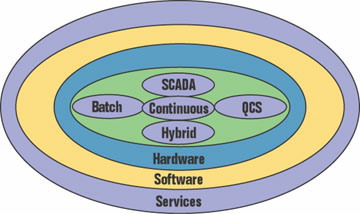

Figure 1: In ARC's

definition, the process automation system implements a selection of traditional

control system functions through a combination of hardware, software, and

services.

A more important immediate observation, however, is that the

practical and technological boundaries between a distributed control system

(DCS), programmable logic control (PLC), and personal computer (PC) control are

blurring. Units traditionally associated with process control are being used in

discrete applications. Likewise, traditionally discrete solutions are used

increasingly in both batch and continuous process control.

"That's

because a look at the underlying technology of today's solutions shows many

similarities," says O'Brien. "Today's different types of control hardware are

constructed from many of the same standard industry components such as Intel

microprocessors. Thus, the only real differences in control systems may lie at

the software level."

O'Brien points out that process and discrete

suppliers are already encroaching on each other's territory. Increased

competition between process and discrete suppliers in the hybrid industries such

as food and beverage, pharmaceuticals, and specialty chemicals are prime

examples. In such applications, the requirements of process and discrete control

are frequently interconnected, and thus combined in the control solution. "A

prime example of a hybrid process is the brewing industry," says O'Brien, "which

incorporates sequential, batch, and continuous process control in the brewing

process, and discrete control in the bottling, packaging, and distribution

processes."

A Changing Controls Market

Does technological

convergence have users a little confused? A small, informal survey of

Fisher-Rosemount DeltaV users found that, when asked to classify their control

solution, some said it was a DCS. An equal number described it as either a

mini-DCS or hybrid controller. One thought it might even be a process automation

system (PAS), although he wasn't quite sure what that term meant. But each user

knew what control functions the system performs and how it fits into his overall

control scheme.

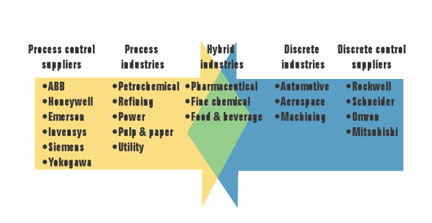

A look at the blending of control functions among

various industries, according to ARC, shows why users and suppliers are

occasionally unsure of the form and architecture of control solutions (Figure

3). Process suppliers are entering the markets traditionally served by PLC

suppliers through the introduction of hybrid controllers. And PLC suppliers are

invading the process control markets with units that perform batch processing as

well as discrete functions. The driving force in either case is industry needs

for total solutions that not only provide control, but generate production,

quality, and maintenance information for MES, ERP, and higher-level IT

functions.

The world of process automation systems includes functions

such as SCADA, batch, hybrid, continuous, and quality control. It is implemented

through a combination of various types of hardware, software, and services.

Traditional hardware solutions include DCS, PLC, and PC control. More recently,

however, hybrid controllers have entered the market poised to capture business

in both the process and discrete industries. This clearly fits the needs of

hybrid industries such as specialty chemicals, pharmaceuticals, and food and

beverage that typically comprise a rich mixture of discrete and process

functions.

But even in the petrochemical and refining industries where

continuous processes reign, there is often a number of smaller batch and

discrete functions. In many cases these functions, along with the continuous

processes, could just as easily be handled in a unified hybrid controller

database. Ultimately, corporations could use this to structure networks and fuel

the data needed for supply chain management, MES, ERP, and IT functions.

Increasingly, manufacturing data that helps improve production

efficiency is the lifeblood of companies in highly competitive markets. Such is

the case for Equistar Chemicals, Houston. By installing MES systems in addition

to its traditional DCS controls, Equistar has created statistical tools and

algorithms for determining optimum feedstock, product run, and logistics

strategies to boost yield and cut costs, according to principal engineer Robert

Brown. Company expenditures for controls last year totaled more than $50

million, but management is confident of a one-year payback because they know

that control projects tend to be the biggest moneymakers, he says.

Furthermore, companies such as Atofina Chemicals in Philadelphia are

using data storage and applied analytical software to better understand control

parameters for quality or yield improvements. By establishing baseline data, the

company can measure system performance and fine tune its processes. Without

detailed statistical analysis, process improvements may be misguided and lead to

replacing a pump when the real problem was just a valve or a pipe.

Figure 2: The process

automation system (PAS) market is predicted to grow to $9.5 billion in 2005.

(Source: ARC Advisory Group)

DCS: The Land of Giants

Continuous process plants

such as refineries, petrochemicals, pulp and paper, steel mills, and textiles

still rely heavily on DCS solutions. Some are moving new applications to hybrid

controllers such as Honeywell's PlantScape or Fisher-Rosemount's DeltaV, but

large-scale legacy systems still control most of the continuous processes. Even

PLCs are not left out of the picture in large continuous process plants. They

are often used for discrete control in such functions as conveyors, motion

control, and machine control.

"DCS really grew out of the heavy process

industries," says George Dolan, a Houston-based controls engineer and consultant

with experience at Lonza Chemicals, Exxon, Nalco, Texas Instruments, STRG

Controls, and elsewhere. "But the market and the equipment have changed

considerably over the years. DCS and PLC worlds are blending as some DCS systems

are now operating on Windows NT platforms and HMI is being added to PLCs. In

fact, a PLC can do nearly everything today that a DCS can do. I know, because I

have successfully crossed that line and put a PLC with HMI in charge of a

continuous process control application. The DCS may still offer some advantages

when it comes to redundancy and hot swap capability, but new PLCs can offer that

today, too."

Dolan considers the PLC to be a less expensive solution to

a given application than DCS. However, over the lifecycle of the application,

say 15-20 years, this will even out as costs for troubleshooting, maintenance,

multiple databases, and communications increase the long-term costs of PLCs. He

confesses that new process software is even helping industrial PCs find a niche

in mixed batch and discrete applications--especially where recipes and formulas

are involved in paints, baking, blending, mixing, batch control, recording,

reporting, and validating. This capability, he believes, is accelerating the

trend toward more open systems, industrial PCs, and truly distributed control

actually occurring in the field as opposed to a remote or centralized DCS

control room. He still maintains, however, that higher-level integration with

MES, ERP, and IT is easier done with a DCS than either a PLC or PC at this point

in their evolution.

"For many years, we have used Bailey Infi-90 DCSs

for process controls and motor starters," says Ben Fairweather, senior control

engineer at Appleton Coated Papers, Combined Locks, Wis. "And we still rely on

them quite heavily. Recently, however, we put in a DeltaV hybrid system for use

on our paper machines to do vacuum control, flow control, level, temperature

loops, and miscellaneous discrete functions such as valve on/off control. In

addition, we use PLCs for motor controls and other discrete applications. DeltaV

provides the HMI for the motors. Therefore, we leverage the OPC flexibility of

DeltaV to handle discrete PLC control as well."

According to process

systems supervisor Peter King, the Ultramar Golden Eagle refinery in Martinez,

Calif., has just about every type of control setup under the sun. "You name it

and we've got it," says King, "but mainly our plant depends on DCS for

continuous process controls--and a few PLCs for ancillary discrete service. We

even have a few old panel control boards that we are in the process of

replacing."

In addition to continuous control, the facility does a small

amount of batch control in blending various grades of gasoline. PLCs are used in

remote operation of valves, emergency shutdown systems, and miscellaneous skid

controls and emissions monitoring. PCs are scattered throughout the plant, but

used mainly for HMI and some gas turbine controls. "But the DCS is really

packaged to fit our particular applications--from hardware to software," says

King. "It's a strong legacy to overcome."

Marty Robbins, process control

engineering manager, Georgia-Pacific, Palatka, Fla., uses DCSs to regulate three

tissue and two kraft paper lines, 13 digesters, power recovery, and a water

treatment plant. "I have Foxboro I/A in power recovery and Honeywell TDC

2000/3000 for most all other processes, plus some Honeywell TotalPlant Solution

(TPS) nodes," says Robbins. Although Allen-Bradley PLCs are used for discrete

applications, some of those functions are handled by DCSs as well.

"I

guess you could say we are slowly migrating all of our process control functions

over to Foxboro I/A," says Robbins. In addition, the plant uses fully redundant

100 Mbit fiberoptic Ethernet for process communications. In the future, he plans

to add advanced control and model predictive control to the legacy systems.

Robbins says, "Not only will this help optimize our processes, but provide more

and better information to support production and maintenance management."

"Overall, I generally use a DCS in applications involving chemicals,

petroleum or petrochemicals, and other large-scale continuous processes," says

Dolan. "For discrete applications such as packaging, product transport, and

other standalone applications, I'll mix PLCs into the control equation. In

addition to the industries already mentioned, the metals industry will often use

a mini-VAX with PLCs for control. The plastics industry normally prefers its own

proprietary controls for such things as injection molding, extrusion, etc. This

may also take the form of PLCs and HMI. Plastics resin reactors, however,

normally use a DCS with triple modular redundancy because the processes are so

complex and difficult to re-start if anything goes wrong."

Figure 3: Control solutions

providers that began in the process or discrete worlds are converging on the

hybrid middle ground and are beginning to encroach on each other's home

turfs.

Hybrid Control: Emerging Solution

Hybrid controllers

are crossing the lines between DCS and PLC solutions. Not coincidentally, they

are targeting the lucrative, fast-growing hybrid industries such as food and

beverage, pharmaceuticals, fine chemicals, and semiconductors. These hybrid

systems handle both process and discrete functions, and are well armed to

compete in the batch processing and supervisory control and data acquisition

(SCADA) markets.

Examples of these new hybrid control systems include

DeltaV from Fisher-Rosemount, PlantScape from Honeywell, the Micro I/A series

controller from Foxboro, Siemens Simatic PCS7, Rockwell ProcessLogix, and the

Centum CS 100 from Yokogawa (Figure 4). As expected, the market is divided into

two segments. One relies primarily on DCS for its process and discrete control

applications; the other mainly on PLCs with single and multiloop controllers for

process functions. Ideally, these control solutions are used in situations where

there is a mix of process field devices integrated with PLCs--or a combination

of PLCs and single and multiloop controllers.

ARCO Alaska, for example,

made headlines several years ago when it purchased a Fisher-Rosemount DeltaV

system to replace Siemens S5 PLCs. Other applications, such as a brewhouse, are

also digital I/O intensive, according to ARC, and require hybrid systems that

can handle large counts of digital I/O. Recently, hybrid control suppliers have

also added to their functional capabilities in enterprise level and supply chain

management. This has helped stimulate new market interest and growth.

"Ideally, a hybrid controller performs regulatory continuous process

(DCS) and discrete (PLC) control as well as batch and logic," says Paul

McLaughlin, director of PlantScape engineering, Honeywell Industrial Control,

Fort Washington, Pa. "The only real difference is in the algorithms that are

used." Hybrids can provide a DCS-grade infrastructure as well as a SCADA

infrastructure, and be used in process automation as well as discrete

automation.

"Automation functions will continue to consolidate as long

as suppliers seek to provide unified industrial solutions," says McLaughlin.

"That may result in cannibalizing some existing DCS and/or PLC business, but if

we don't do it, the competition will. We're in the business of providing

scalable, high-availability embedded control solutions, so we compete with both

DCS and PLC solutions--but not with PC control products."

Hybrid systems

are quite versatile. They can offer HMI/SCADA functionality, complex continuous

and discrete control, or demanding refinery and petrochemical functions; from

less than 10 up to 20,000 or 30,000 I/O. Hybrids also offer use of open,

interoperable bus technologies including Foundation fieldbus, AS-i bus, Profibus

DP, and DeviceNet. They often feature open standards such as OLE for Process

Control (OPC), XML, and ODBC. And they excel in integrating enterprise planning

systems with lower-level devices such as wireless phones, pagers, and PDAs.

Tom Shaw, automation manager at Cargill/Vitamin E in Eddyville, Iowa,

describes how his plant recently switched over from a combined DCS/PLC control

environment to a hybrid control system to achieve a common configuration

environment and a single integrated database. "Eliminating separate databases

for discrete and process control is a major operating advantage," says Shaw.

"Right now, the hybrid control system handles discrete, batch, and process

control--plus it interfaces to our legacy DCS system and provides a unified

database. Hybrid control simply meets all of our control and data needs. It's

safe to say that all of our future control requirements will migrate to hybrid

control as well."

Vernon Mills Textiles in Trion, Ga., is moving from a

System 3 DCS to a hybrid control system. "Most of our textile dye and finishing

operations are now controlled by a DeltaV hybrid controller," says process

control engineer Randy McDonald. "We are making the move due to lower installed

costs including smaller footprint, reduced installation and maintenance, fast

configuration, and the wealth of information available using Foundation fieldbus

and smart field devices. It is taking the place of a mix of 4-20 mA process and

discrete control solutions regulated mainly by the System 3 DCS.

"DeltaV

also offers us response times in the nanosecond range as compared to about a

half-second previously," he continues. "But what really sold us on the solution

was its ability to recover instantly after system shutdown or power failure.

There are no lengthy startup procedures, just normal checkout as everything

comes back up automatically. Previously, control functions were performed

differently by different operators. Now, everything is recipe-based and

virtually foolproof."

Gideon Richter Pharmaceuticals, Budapest, Hungary,

recently installed a PlantScape hybrid control system to integrate a reverse

osmosis (RO) water purification unit into its overall synthetic hormone

production facility. The objectives of the installation were to create automatic

batch reports, further develop and refine production technology, fulfill FDA

validation requirements, and identify and correct production deficiencies.

Specifically, the control system was implemented to reduce batch variances and

to minimize operator failures.

It also had to integrate additional

control elements without making major changes to existing facility hardware or

software. As a result, a single PlantScape controller was dedicated to handle

all of the data collection and control requirements of the RO water unit.

PlantScape's rotary station capability allows engineers to log onto the system

on their PCs to check data and monitor system performance. The familiar NT-based

operator interface also allows drag and drop configuration of I/O, continuous,

logic, motor, sequence, batch, and advanced control functions through a library

of function blocks.

Francisco Campa is head process development manager

at Dixie Group Carriage Industries, a textile dyeing plant in Calhoun, Ga. His

rationale for implementing a DeltaV hybrid control system is: "It does more than

just control. It organizes, manages, and communicates data while it also manages

multiple processes. We use it to control temperature, level, flow, and pressure,

and to interface with PLCs that regulate motors, on/off valves, and

miscellaneous discrete equipment. Thus, we have the highest level of confidence

in the data from these operations as they are fed quickly and accurately into a

corporate management system. Plus, it offers diagnostics and testing

capabilities that are not available with some PLC solutions."

PLCs:

Old Solution, New Twist

As we have seen, even in the land of the process

giants, PLCs have played an important role in the many discrete control

functions that necessarily support most continuous process applications.

Mike La Rocca, senior process engineering specialist, Solutia Industrial

chemicals, Sauget, Ill., says his plant depends on DCS for continuous process

operation--about 75% of the applications are continuous process control. But 25%

are batch and discrete operations. For those (bagging, drumming, manufacture of

solid pastilles, and batch mixing), he depends on PLCs. "I feel in the not too

distant future it won't make any difference what controller you use, but how you

configure it, program it, and what software you use to execute the

functionality. We do a lot of batching, blending, and bagging in producing

chlorines, chlorobenzenes, and other additives used in the manufacture of animal

feeds, plastic bags, and wrappings. And most of that is controlled by PLCs."

The Climax Molybdenum Co. Mine and Mill in Parshall, Colo., uses a mix

of PLC, DCS, and SCADA. "Our controls are probably 60% PLC/HMI and 40% DCS,"

says Al Splettstosser, control systems coordinator. The facility uses PLCs with

HMI to control underground mining functions including water treatment, mine

ventilation, and more than 15 miles of conveyors. DCS is used to control mill

processes including cascade and ratio controllers to regulate loading, the mill

power drive, paper feeders, water controls, and grinding functions.

The

basic DCS system was installed in the early '80s mainly to control electric

power usage. It then spread to other functions such as water and wastewater,

pumping, and ventilation. In addition, Foxboro I/A is used to transfer

information from the PLCs to DCS. The only batch application is blending some of

the powdered reagent used in the processing. This is accomplished using PLCs.

"Because we use Allen-Bradley PLCs with HMI and historian software, we

might consider installing Rockwell's ProcessLogix to integrate our databases and

discrete and process controls in the future," says Splettstosser. "Until then,

DCS is our primary continuous process control solution. It provides the power

and applications we need without developing interfaces for incompatible products

with different protocols."

Just as hybrid controls based on DCS

technology are adding discrete control functionality, new PLCs are adding

process muscle to their discrete control capabilities. "ProcessLogix is simply

Rockwell's version of our PlantScape," says Honeywell's McLaughlin. "And its

ControlLogix is a next-generation PLC product that features discrete networking

via ControlNet. Furthermore, both can be applied as board-level products and

added to a controller to provide a wide range of solutions--both discrete and

process."

The Hexcel Corp. polymer plant in Decatur, Ala., recently

installed ProcessLogix on its polymer fiber line to optimize its mixing,

stretching, chemical treatment, and extrusion processes and increase overall

efficiency. The polymer line uses a mix of both batch and continuous process

control. "We needed efficiency without high dollar investment," says plant

engineer Jim Peppers. "ProcessLogix allows us to improve control and reduce

engineering and maintenance costs at the same time."

Since ProcessLogix

uses one common database for the server, controller, and operator interface, it

is inexpensive to install and maintain. It also offers drag-and-drop function

block programming, a library of process control functions, and a global

database. Plus, it offers the control functions normally found in traditional

DCS solutions.

Jeff Pierson, process engineer at BAE Systems Royal

Ordnance North America, Kingsport, Tenn., also uses a mix of PLC/HMI and DCS

solutions in the process of manufacturing high explosives. The facility's most

recent installation uses PCS7 controllers (PLCs) from Siemens, which perform

both discrete and process functions in the batch chemical manufacture of various

grades of explosives. There is also a Foxboro I/A DCS system that controls

distillation columns and related systems in the organic acids plant, and some

older Siemens and Allen-Bradley PLCs that control switches, valves, and pumps in

water, steam, and utility areas.

"In addition to the batch capability,

one of the reasons we chose PCS7 was because we already had PLC I/O in many of

these scattered production buildings," says Pierson. "We also needed the hot

backup capability provided by Siemens for our exothermic chemical reactions, and

wanted to use sequential function chart rather than ladder logic for programming

our applications."

"As PLCs and DCSs move toward each other

technologically, GE Fanuc continues to add functionality to its existing family

of products by offering process extensions or programming tools that can offer

truly integrated system solutions," says Lance Miller, open process manager for

GE Fanuc, Charlottesville, Va.

Open process solutions are giving

customers more functionality, ease of use, and the connectivity required for

scalable, integrated solutions. The city of Hazel Crest, Ill., needed a potable

water delivery system that could coordinate multiple remote pumping and metering

stations as well as control chemical treatment of the water. "Ideally, the

system should also integrate with a paging system to alert an on-call operator

of critical situations," says treatment plant engineer Jerry Davis. "It also had

to be affordable, flexible enough to meet changing requirements, and offer quick

return on investment."

The solution features GE Fanuc 90-30 PLCs and

Cimplicity HMI software, and provides communications through spread-spectrum

radio. Cimplicity HMI provides the graphics and alarming capability, as well as

standard historical evaluation tools. The solution has provided a return on

investment in less than two years. In addition, it generates daily reports for

environmental compliance, virtually eliminates manual data collection and device

control, and automatically logs system performance. "Best of all, it has cut

overtime in half," says Davis, "and we can even monitor system performance from

off site via phone."

PCs: Ready for Process?

The market for

PC-based process control has grown remarkably during the last several years,

encroaching mainly on proprietary PLC applications, according to YeeYeen Wang,

national director for HMI and panel PCs, Advantech, Fremont, Calif. One must

realize, however, that PC-based control is starting from a much smaller market

share than PLC, DCS, and hybrid control solutions.

"Often, PCs are used

today to control machinery using remote I/O modules as a linkup," says Wang. At

higher levels of integration with MES, ERP, IT, and management databases, PCs

have an open systems advantage over both DCS and PLC solutions. "We find this

especially true in the food and beverage, water and wastewater, semiconductor,

and pharmaceutical industries. DCS and PLC solutions make sense in continuous

production of stable products in long-term markets. The inherent flexibility of

PC technology, however, better accommodates constantly fluctuating markets,

products, and services. And in the future, web connectivity for remote

monitoring and control is a major plus for users."

To allow for market

and technology changes, Advantech contracts stipulate that they will stock the

customer's necessary hardware and software for a specified period of time, or

provide a three to six-month advance notice of anticipated product or technology

changes. This provides customers with replacement products to maintain current

solutions, or an opportunity to plan an upgrade to the next level solution.

PC-based control made big news several years ago when Moscow-based AK

Transneft, one of the world's longest crude oil transmission systems, installed

300 networked PCs to provide supervisory control and data acquisition to its

pipeline network. The Windows-based PCs running Genesis HMI/SCADA from Iconics,

Foxborough, Mass., generated savings of more than three times that of

traditional UNIX and DCS systems, according to Victor Saenko, chief technical

officer. It monitors more than 187,000 digital and analog tags, and also

provides early warning of leak detection along the transmission system.

Since then, PC-based control has been used successfully in various

process applications, especially water and wastewater, pilot chemical and

pharmaceutical facilities, and food and beverage applications. Still, there are

reservations about using PCs in large-scale continuous processing plants.

"It is certainly feasible to use a PC to replace a DCS or PLC," says

Campa, "but not advisable for us at this point. If a PC is only collecting data

and crashes, the production process continues on regardless. But if it is

controlling the processes, shutdown and startup could be expensive--not to

mention possibly hazardous for machinery as well as humans."

"We use PCs

for SCADA and data collection--and even some non-critical control applications,"

says Cargill's Shaw, "but I'm not ready to trust my plant to a PC just yet for

reasons of safety, security, reliability, and mean time between failure."

"At Solutia Industrial Chemicals, it's against corporate guidelines to

allow a PC to control production processes," says La Rocca. "We deal with

hazardous chemicals and the safety issues are too great--plus consistent,

high-quality production is vital. There are just too many occurrences of PCs

locking up that require system shutdown and re-start."

Nalco Chemical

Co., however, operates a large pilot plant in Illinois whose function is process

development and scale-up to full production manufacturing. One of its processes

uses a reactor whose reactants are fed at multiple feed points using

positive-displacement pumps. To ensure accuracy, Nalco decided to integrate a

PC-based SCADA system to control the speed of the pumps through a feedback PID

loop. It used National Instruments Lookout HMI/SCADA software and Fieldpoint

distributed I/O to implement the application. All of the hardware was installed

in a NEMA 4 enclosure along with a Dell Pentium-based PC.

According to

Vivek Nayak, president of Vista Technology, a system integrator in Schaumburg,

Ill., the system was installed and commissioned with practically no operator

training. In addition, the PC-based system provided accurate, automated logging

of experimental data, easy data retrieval, and significantly increased the speed

and efficiency of the entire developmental research process.

Choices,

Choices, Choices

In selecting the right process control solution, one can

no longer assume that a certain type or class of product is the right answer. As

technologies and control solutions merge, it is more important than ever to

judge on the basis of functionality, affordability, and overall lifecycle costs.

As we have seen, there is a considerable amount of discrete control even

in the large continuous process industries. Thus, the capability to perform

hybrid control functions will continue to be a moving force in the marketplace.

But what really is hybrid control, anyway? Is it the ability to function through

one unified control and management database? Is it the ability to do both

process and discrete control? Is it both control and database capabilities--or

those two plus something else? Even the suppliers and industry experts don't

agree on these points. Furthermore, what determines how efficiently and

effectively control is implemented? If everyone is trending toward the use of

the same (Intel) microprocessors, is it, as some would suggest, merely a matter

of software implementation?

Until such questions are answered thoroughly

and satisfactorily, it is more important than ever to carefully evaluate control

solution functionality. Kevin Stively, senior process controls engineer with the

engineering firm of Parker, Messana & Associates in Tacoma, Wash., attempted

to answer that question for the pulp and paper industry several years ago. He

began by postulating a theoretical application for a process unit that had 110

analog inputs, 68 analog outputs, 40 discrete (non-motor) inputs, 15 discrete

(non-motor) outputs, 50 motors with three discrete inputs (ready, running, and

overload), plus one output (run), and 24 PID loops.

His conclusion?

Large processes with more than 2,000 physical I/O points and a few hundred PID

loops might be best served by a traditional DCS. Smaller processes could

probably be controlled adequately by a mini-DCS, hybrid control system, or

PLC/HMI solution. The cost of these other solutions were about equal, and ran

44-48% less than that of a DCS. One of the most important criteria is that of

I/O selection and mix (analog, discrete, advanced process control, etc.).

But perhaps even more important than his conclusion is the methodology

used to evaluate control selection. He begins with a thorough analysis of the

process and its control needs, including types of control, I/O, and

communications interfaces. He then considers the strengths and weaknesses of the

various control platforms (DCS, PLC/HMI, mini-DCS, etc.). Design considerations

follow with an analysis of control architecture and where and how control should

be implemented (including scan times, system response, etc.). The inevitable

capital cost comparison (per I/O point or other reasonable comparison), is

followed by a benefits comparison based on both current and projected needs. A

review of various solution limitations is linked to configuration requirements.

And finally, training and service/maintenance considerations are discussed.

So there are no easy answers; simply lots of choices. Review them wisely

and carefully. For the time being, at least, functionality rules!

ICONICS Background Information

Founded in 1986, ICONICS is a leader in the

development of Web-enabled industrial automation and manufacturing intelligence

software for Microsoft® Windows® operating systems. Offering the industry's only

suite of fully-integrated OPC-based components and products, GENESIS32™

Enterprise Edition is available for Windows XP, 95, 98, Millennium, and 2000,

and Windows NT®. Pocket GENESIS™ for Windows CE and Pocket PC was built from the

ground up based on ICONICS' OPC-To-The-Core™ framework. BizViz™ is a suite of

manufacturing and business intelligence products, which bridge the gap between

manufacturing and corporate business information systems. BizViz is designed

around Microsoft .NET technology, Microsoft SharePoint™ and runs on Microsoft

server 2003. ICONICS also offers a complete set of Plug and Play automation

components, including best-in-class OPC ActiveX® Controls, OPC Toolkit, Human

Machine Interface (HMI), Microsoft SQL Server®–based data logging, Multimedia

Alarming, and Supervisory Control and Data Acquisition (SCADA) products. ICONICS

is a Microsoft Gold Certified partner, represented in over 50 countries and has

in excess of 150,000 products installations worldwide. For more information

contact ICONICS at (508) 543-8600 or visit us online at www.iconics.com.

© 2005 ICONICS, Inc. All rights reserved. GENESIS,

GENESIS32, Pocket GENESIS, Embedded GENESIS, GraphWorX, AlarmWorX, TrendWorX,

DataWorX, ProjectWorX, VCRWorX, TraceWorX, WebHMI, GenBroker, ControlWorX,

MachineWorX, ToolWorX, ToolBoX, BizViz, ReportWorX, BridgeWorX, PortalWorX,

MobileHMI, Visualize Your Enterprise, and OPC-To- The-Core are trademarks of

ICONICS Inc. Microsoft, Windows, ActiveX, Visual C++, Windows NT, and Visual

Basic are either registered trademarks or trademarks of Microsoft Corporation in

the United States and/or other countries. IBM and PC are trademarks of

International Business Machines Corp. Other product and company names mentioned

herein may be trademarks of their respective owners.

|